| |

|

|

Winner Foundries and Manufacturing, Inc.

5655 Marshall St.

Arvada, CO 80001

303-424-5509

One of the newest and finest foundries in the West,

since 1922 Winner has progressively kept pace with market

demands for high quality metal castings. |

|

|

|

|

|

|

|

|

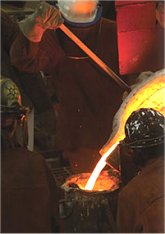

Sand Molding at

Winner Foundries

and Manufacturing, Inc.

|

|

High quality castings depend on quality patterns,

uniform and properly mixed sand, and high grade pouring

metals heated to the proper temperature.

Winner Foundries exercises all possible control to

maintain high standards on casting beginning with the

sand, which is tumbled, fluffed, aerated and moisturized in a

fully automated Muller machine. When the proper

mixture has been achieved, the sand is delivered to the

five molding stations through an overhead conveyor system.

At the stations it is used to individually pack and set

each flask, thereby making the mold to be poured.

|

Flasks (molds) are placed on a track at the assembly station

in-line to the furnaces. Furnaces and the

temperature of the molten metal are controlled to

± 1 degree Celsius through the use of digital

pyrometers. The molten metal is delivered to the

assembly station by an overhead system and

poured into the molds. Immediately after

cooling the molds are opened and the casting is

extracted and stacked for finishing. Each

casting is spot checked for faults,

deposits and porosity.

|

|

|

|

|

|